Ceramic matrix composite materials

Our expertise in "Composite Materials and Processes" meets industrial competitiveness needs by contributing to the development of aerospace and space structures that combine lightness with temperature resistance exceeding that of superalloys. We develop ceramic matrix composites (aluminum oxide Al₂O₃, silicon carbide, glass-ceramics, etc.) to provide a "material solution" across the full range of thermostructural applications.

The targeted applications include structural components exposed to flames or extreme temperatures in aircraft, launchers, satellites, and engines, where reliability must be ensured. We design, develop, and manufacture new materials, from semi-finished products to complex architectured structures, up to a semi-industrial scale.

To go beyond the trial-and-error approach often encountered in the industry, we also develop digital tools and methodologies to design and manufacture these high-value-added materials and structures. This allows us, for example, to reduce design and qualification phases for industrial partners (virtual testing) and to understand the influence of manufacturing process parameters on the microstructure and properties of the produced materials (process modeling).

Our research areas

Our Expertise

The design of innovative solutions :

Through advanced numerical modeling methods applied to material research, we offer effective and customized numerical modeling solutions for each challenge.

The formulation and implementation of oxide matrices in composites, enabling research related to circularity or functionalization.

The definition and implementation of methodologies and processes for the production of prepregs and tow-pregs in oxide CMCs, for draping, AFP, or filament winding.

The development and implementation of architectured solutions.

Multi-instrumented thermomechanical characterization, enabling rapid material screening or identifying optimization opportunities.

Raw material and composite formulation

- Formulation and scale-up (manufacturing automation and volume increase)

- Characterization of suspensions

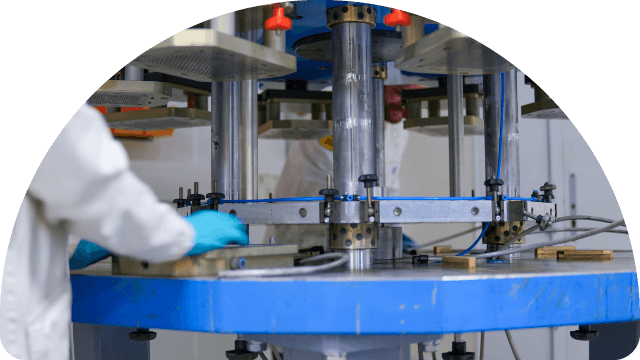

- Development of composite parts through draping

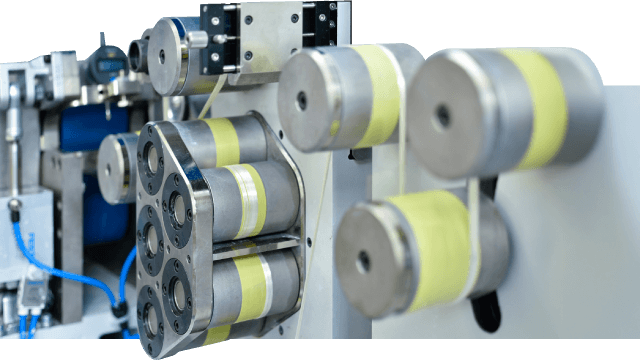

Oxide CMC impregnation

- Development of CMC prepregs from any compatible fiber-matrix pair.

- Optimization of process parameters to produce a reproducible tow-preg compatible with automated manufacturing processes.

- Optimization and implementation of image and data processing algorithms to monitor the process (phenomenon anticipation, NDI, etc.).

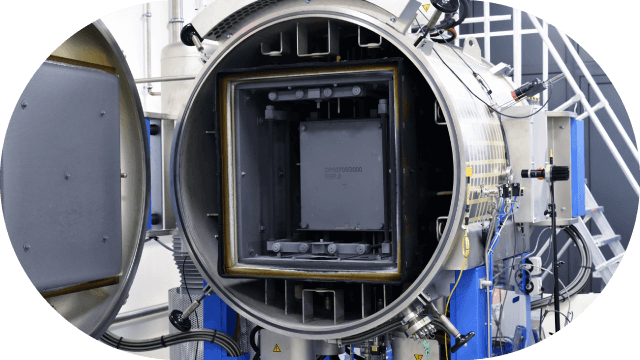

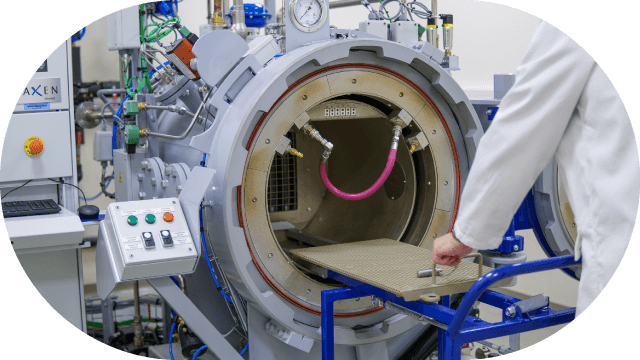

Injection (STM) and Silicidation (Melt Infiltration - MI)

- Development of injection processes for oxide CMCs and silicon carbide, scaling up to pre-industrial pace.

- Optimization of the molten metal alloy infiltration process (silicidation). Scale-up and developments on UHTCMC.

- Development of monitoring activities (STM and MI processes), development and optimization of image and data processing algorithms. Mid-term application: development of an autonomous furnace.

Creation of architectured structures and proof of concepts

- Mold/part design

- Manual draping / automated implementation with our partners (AFP, filament winding, etc.)

- Selection and optimization of core material integration

- Multiple stresses studied: thermal and fire protection (e.g., reusable launcher feet), chemical inertia, and geological compression, etc.

Modeling, simulation, AI-assisted data processing, and thermomechanical characterization

Thermomechanical characterization of materials under fatigue up to 5Hz, 20kN, and 1700°C (with thermal fluxes exceeding 2MW/m²). Our multi-instrumented test bench allows precise control of thermal gradients and other phenomena that may occur during testing. This high versatility also enables material screening with facilitated discrimination.

Optimization and implementation of digital solutions aimed at accelerating maturity, supporting the development of innovative structures, and reducing development time, with applications for:

- Automated processes (AFP, FW, etc.)

- Non-destructive testing (upstream or downstream of manufacturing)

- Optimization of robot trajectories and identification of singularities

Development and use of artificial intelligence for the implementation of materials. Applications range from non-destructive testing (online or offline) to the development of software modules aimed at improving equipment reliability and even making them autonomous.