The DePÔz demonstrator illustrates the growing maturity of the LMD-p process through the development of design and manufacturing rules, making the IRT Saint Exupéry a major player in the industrialisation of this technology.

Laser Metal Deposition is a promising metal additive manufacturing technology for industrial applications. Indeed, the ability to adapt manufacturing parameters according to the targeted application and the direct deposition of material offer repair and functionalization possibilities. However, this technology still needs development in terms of design capabilities but also metallurgy understanding and interfaces characterization. The DePÔz project is intended to fit in this scope. This project, 50% financed by “le Programme des Investissements d’Avenir” (PIA) gather together 15 industrials and academics members distributed on all the value chain of the metallic additive manufacturing, from LMD machines supplier to important Aero groups such as Airbus or Safran, through tier-1 suppliers parts manufacturers.

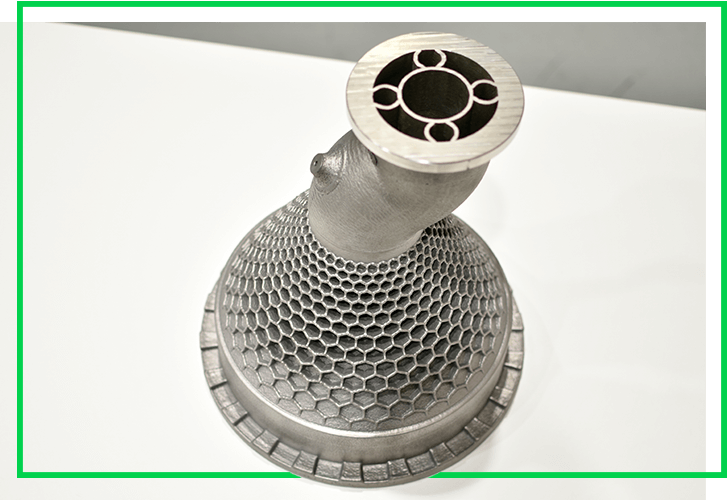

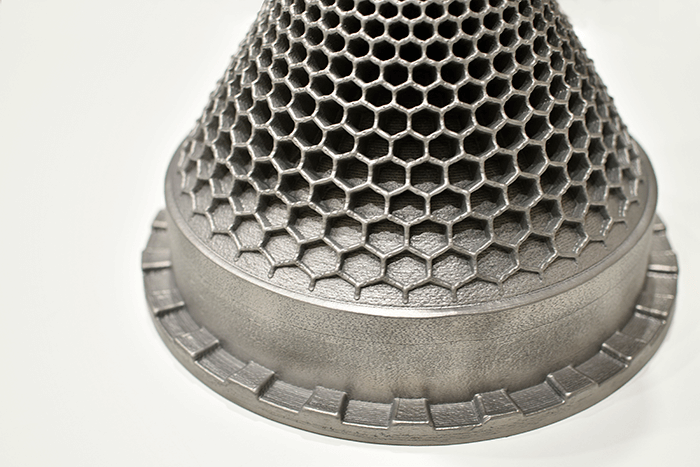

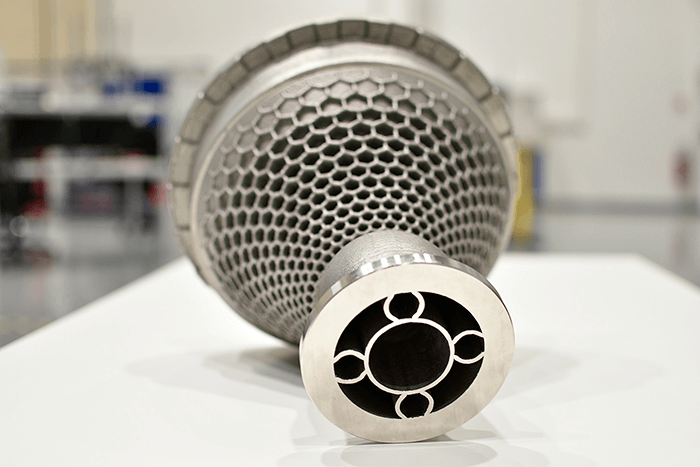

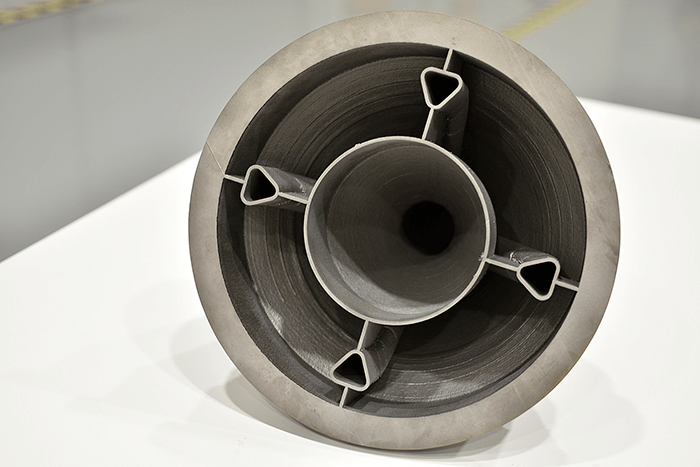

One of the main results of the DePÔz project is the definition of design guidelines associated to LMD-p process. The example presented in this article, an 18 Kg demonstrator made in alloy 718 (nickel-based superalloy widely used in the aerospace industry and power generation), is an illustration of the outcome of many years of research work. It is the result of a collaboration between IRT Saint Exupéry and Poly-Shape (AddUp Company). It allows to demonstrate process abilities but also to highlight its limits linked to its actual maturity level. This part gather various complexities inherent to LMD-p process, such as intersections, changes of section, overhang zones, elbow zones or functionalization on thin freeform surfaces.

The success of this shared development is based on Computer Aided Manufacturing and Design (CAMD) but also on process, parametric and methodologic developments on technological samples carried out within the DePÔz project. This collaboration results in a robust and efficient scale transfer for complex part manufacturing. Indeed, only 2 weeks were necessary to manufacture the part, including development carried out on all elementary geometries that constitute the global complex part. Dimensional control of the complex part allows quantifying deviations concerning the theoretical dimensions (CAD). These deviations underline the LMD-p process complexities and the need to master all elements of the production chain, above all thermomechanics history that is the key for a successful building. Additionally, work performed allowed the evaluation of various non-destructive technics regarding specificities of LMD-p parts. The sum of all these elements offer to IRT Saint Exupéry and DepÔz project members to have a better understanding and vision of LMD-p process limitations and identify remaining technological locks to lead this process towards industrial uses.

About Poly-Shape

Poly-Shape, a subsidiary of AddUp, is a global service provider for parts design and production with AM technologies. With almost 15 years of experience in PBF and more than 5 years in DED on a large diversity of application typology (materials, geometry), Poly-Shape is one of the most advanced company in France in the field of AM process engineering and operation.

“We were proud to participate in a large multi-industrials project such as DePÔz. As a technological developer, we have accompanied the IRT Saint Exupery in its DED process skills improvement and, in the meantime, oriented the project roadmap to address technical problematics that currently limit the DED industrial spreading. We could bring our DED process expertise to co-design, program and produce a challenging final demonstrator closing this 4-years project. It ended up to this Proof of Concept that shows actual technical opportunities and realistic process limitations. We have appreciated the faculties of IRT to work rigorously with scientific methods. IRT Team has always proven good ability to listen and understand industrials needs and to answer with suitable technical solutions. Their high level in materials sciences helped us to extend our knowledge about materials processed with this AM technologies for critical aerospace and industrials parts.By increasing the L-DED process comprehension, this project could make the technology acceptance more possible by Industrials.” Arnaud Ferrandez, Project Manager, Poly-Shape

DepÔz project members

About FIT Additive Manufacturing

These activities are part of the FIT Additive Manufacturing initiative, created in 2016 and bringing together the IRT Jules Verne, M2P, Saint Exupéry and SystemX.

This inter-IRT alliance creates the conditions for optimizing the activities of the 4 institutes in the field of additive manufacturing, in order to meet the strategic challenge of developing these technologies, particularly for the benefit of the aeronautics and space industries.

This pooling, coordinated by the IRT Saint Exupéry, also makes it possible to propose a complete offer to the industrial partners, thanks to the technical specificities and technological positioning of each institute. On a daily basis, this translates into the construction of projects, between the IRT at the origin of the initiative and those with complementary skills, in order to benefit from better access to the right skills and useful means.

Contact

Céline Larignon

Project manager Metallic Materials and Processes

celine.larignon@irt-saintexupery.com

Lisa Nicolas

Additive Manufacturing Engineer

lisa.nicolas@irt-saintexupery.com