The need for products to be recyclable and reusable, in a context of eco-circularity, is now prompting many manufacturers to turn to demountable adhesive bonding. The IRT Saint Exupéry has positioned itself as a key player in bringing together manufacturers, solution providers and academics to focus future activities in response to industrial needs. Here’s a closer look at the IRT Saint Exupéry’s involvement.

Why invest in removable bonded assemblies?

Current and future environmental constraints, as well as our social and environmental responsibility, now require us to make particularly innovative R&T efforts, and this applies to bonded assemblies. Although these assemblies have many applications in industry because of their many advantages – multi-material assembly, distribution of mechanical stress, weight reduction. – there is still a major obstacle to be overcome so that this technology meets the challenges of the circular economy.

Adhesive joints must be able to be dismantled:

– in the event of non-conformities in the bonding (for parts with high added value),

– for maintenance, to enable certain parts to be repaired and reassembled,

– to separate materials so that they can be recycled,

– in some cases, to replace screwed assemblies.

One of the main challenges is to ensure that bonded assemblies can be dismantled ‘on demand’, without altering functionalities in service, such as thermal or electrical conductivity, mechanical and thermal performance, watertightness, vibration resistance, etc.

Today, there are a some state-of-the-art solutions, but few commercial ones. Against this backdrop, the IRT Saint Exupéry has invested in a number of projects.

The CODEX project:

The CODEX project was launched in 2021 for a period of three years, with partners Continental, Actia and Thales Alenia Space as industrial members. The aim of this exploratory project is to respond to industrial applications with their specifications. The first objective was to establish the state of the art of existing solutions and their level of maturity. Various solutions were identified, developed and evaluated in terms of their potential to meet the specifications of industrial applications. The development of these solutions required synergy between the skills of the IRT Saint Exupéry (materials and electrical teams) and the expertise of external partners. The next stage of the project is currently being prepared, with the aim of increasing the maturity of the solutions identified as the most promising.

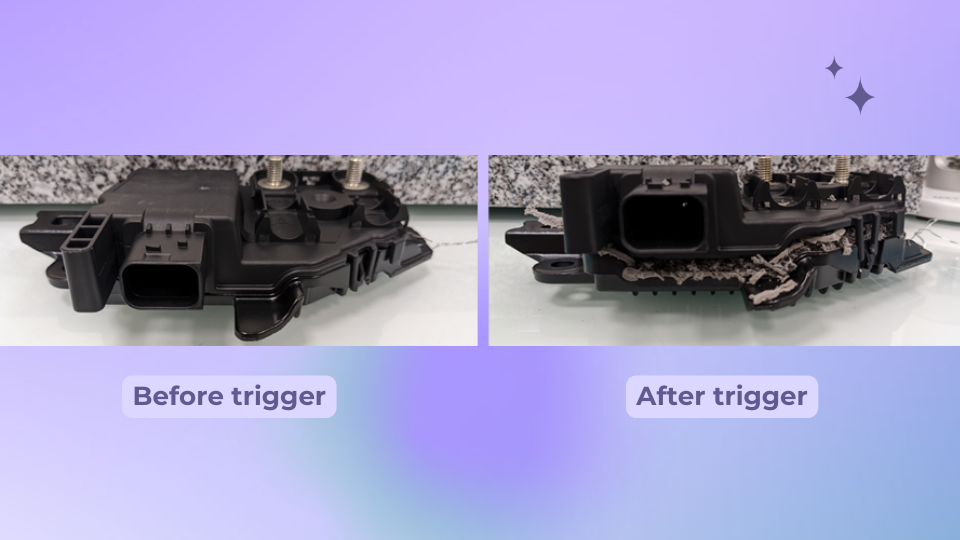

Proof of concept of the bonding of a case: before and after “trigger” / activation of demountability

Meeting industrial needs

One of the objectives of the IRT Saint Exupéry is to bring together all the players involved in the field of demountable bonding in order to meet industrial needs as effectively as possible. To this end, it has organised a number of events alongside all its potential partners. For example, a theme day was organised at the IRT Saint Exupéry site in Talence, bringing together a large number of players in the field of disassemblable bonding, in order to gather together their needs in terms of disassembly. The day brought together a number of manufacturers from different fields (automotive, space, aeronautics, batteries, etc.) as well as academics and solution providers.

The AVAR project

The IRT Saint Exupéry and CNES have joined forces on an ‘Eco-design’ R&T project. During eight months of research and development, the aim will be to use the properties of vitrimer materials, based on the extensive research carried out by the IRT Saint Exupéry on this subject, to develop an bonded assembly with a reversible vitrimer adhesive, whose disassembly temperature is controlled. The solutions developed are designed to meet the needs of the space industry: the repositioning/reuse of bonded assemblies, the replacement of short-life parts (thermal protection, sensors, electronic cards, batteries, etc.), the recovery of high-value-added parts, and the replacement of screwed assemblies with reversible bonded assemblies. The technical approaches will focus on custom formulation and characterisation of vitrimers to suit assembly (removal) and disassembly processes.

The approach consists of using the properties of vitrimer materials, thanks to the extensive research carried out by the IRT Saint Exupéry on this subject, for new applications such as demountability. Vitrimers will be used as adhesives with control of the disassembly temperature, and their compatibility with industrial equipment will be demonstrated.

« A number of projects are currently underway on the industrial future of removable bonded assemblies. The IRT Saint Exupéry is mobilising its multi-skills, supported by its network of partners, to come up with industrial solutions that meet environmental challenges’ concludes Sara KIRCHNER, project manager for surfaces and assemblies at the IRT Saint Exupéry ».