IRT Saint Exupéry pursues a series of portraits devoted to the men and women who best represent the institute: its researchers. Their high-level skills and wealth of experience contribute hugely to IRT Saint Exupéry’s performance and unique position, which is so crucial for its members and partners.

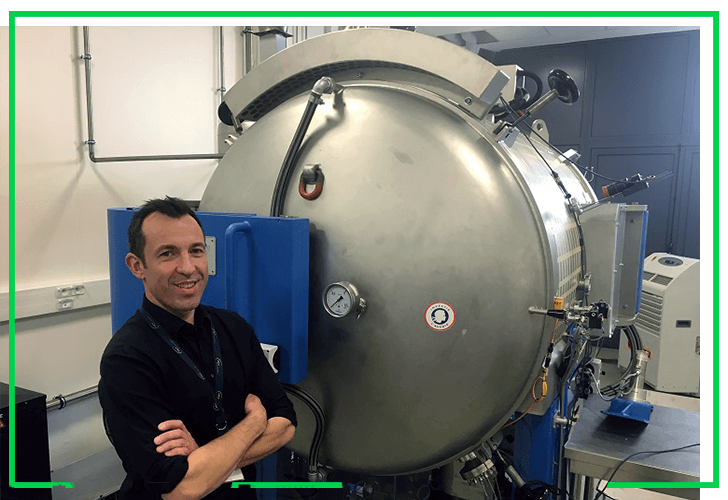

Laurent Ferres, age 42, is a structural mechanics engineer and head of materials platforms for IRT Saint Exupéry and the Bordeaux site. As Laurent explains, “our aim is to make the French R&D system more fluid”.

Can you tell us about your career?

I studied in Perpignan, where I’m from, followed by Montpellier and Aix en Provence. Then I worked at the Michelin research centre in Clermont-Ferrand on tyre wear and endurance. Afterwards, I stayed at Rio Tinto (formerly Aluminium Péchiney, now Alteo) near Marseilles for a little over 10 years, working on oxide powders (aluminium oxides, zirconium and bauxite) and manufacturing processes as head of industrial development. These powders are used in a wide range of applications, including glass, concrete and ceramics. I travelled extensively to the United States, China, Taiwan and Indonesia to start up production workshops. I joined IRT Saint Exupéry at the end of 2016 as head of the materials platforms for the Bordeaux site.

My childhood dream was to be a doctor. But after failing my first year at Montpellier, I decided to switch to physics. Today, in hindsight, choosing science has meant I’ve been able to enjoy a more varied career.

What are your specialties on the bordeaux site?

We work mainly on materials for aeronautics and space. Ceramic matrix composite materials (CMCs), which are particularly resistant to extreme conditions, really have a long history in Nouvelle-Aquitaine region, with Safran Ceramics (formerly Héraklès) making them for engines. We focus on CMCs for very hot internal engine parts, made today from super metal alloys, to raise the temperature and lower consumption.

The other specialty in our Bordeaux entity are innovative assembly technologies that replace current technologies (drilling, bolting and chemical surface treatment) to reduce weight and environmental constraints and cut costs. Our main clients in this area, ArianeGroup and Safran Composites, are developing extensively in this field.

In partnership with Arts & Métiers, we’re developing a part of the Andduro project on additive manufacturing, supported by our colleagues in Toulouse. We’re studying possibilities with Thales and Dassault on artificial intelligence for Bordeaux and collaborative digital platforms for embedded systems.

COMPOSITES COMPETENCES

Project : Oxyde Voie Liquide 2

Cmc Platform: Injection Moulded Ceramic Part – Characterization – Melt Infiltration Furnace

INNOVATIVE ASSEMBLIES & SURFACES COMPETENCES

Project : Innovative Assemblies Innovative Assemblies Platform: Lasers – Atmospheric Plasma Technologies – Kuka Robot

MAIN MEMBERS

INDUSTRY MEMBERS: SAFRAN CERAMICS . SAFRAN COMPOSITES . ARIANEGROUP

ACADEMIC MEMBERS: I2M . IRCER . CIRIMAT . LCTS

What noteworthy results have been achieved by members?

We have very good, specific platforms that are capable of incorporating the entire value chain, from preparation to characterization, on innovative assemblies with lasers and robots, and on ceramic composites with the ceramic powder injector and siliconizing furnace[1] for consolidating the silicon carbides. We obtained the first results with a rise in technological maturity for the innovative assemblies project and two patents on the wet oxides project, which aimed to develop an oxide-oxide prepreg[2] for rear engine body applications. Two requests for inventions are in progress on the wet oxide 2 project. Last of all, we made a transfer to Safran Ceramics and filed a patent on the powder infiltration technology with a multi-object process that can produce several parts in a single cycle to ramp up this pre-industrial process.

On the academic side, our two post-docs from CIRIMAT and IRCER[3] have discovered things in a few months that are amazing for me, who has worked for 10 years in powder transformation processes! Functionalized oxide powder granules usually go as high as several hundred microns, and rarely less than 50. Our post-doc Marc Singlard at IRCER, who’s working on the wet oxide 2 project, has obtained much finer granules using relatively simple technology. This would mean we could, from a technical perspective, consider making some progress in fiber impregnation for producing, for instance, aeronautical parts for rear engine housings. Potentially solving this scientific problem would open up new avenues in terms of the industrial process.

What do you like at IRT Saint Exupéry?

I like the fact that my job is very varied, and that I wear different hats: I’m responsible for the site platforms, managing the site, setting up the project, and acting as the go-between with the Toulouse site and business development. When I’m at the edge of my technical expertise – on artificial intelligence, for example, or the digital platforms – I know I can count on the Toulouse teams.

The management part is really very rewarding for me. I’ve got a very good team in Bordeaux, and they’re quite young and are gradually becoming independent. It’s nice to see them assert themselves because they’re the future of IRT. Everyone does their bit. What I was looking for when I came to IRT was to create something new, and this shared feeling gives plenty of impetus and fluidity to communications. I didn’t experience this pioneering mindset in my earlier professional lives, where there was already a history. The counterpart is that the system is very complex, what with the needs of manufacturers and academics, IRT’s independence and collaborations with other technical centres. It’s up to all of us, at our own level, to make our French R&D system more fluid.

[1] Silicide transformation, silicide being a combination of silicon with another simple element.

[2] A prepreg is a semi-finished product in which a reinforcement is pre-impregnated with a matrix, which makes it highly resistant to breakage. In the case of CMCs, the matrix is a ceramic powder and the reinforcement is ceramic or sometimes carbon fibre. This composite, which is heavily charged with micro-sized ceramic particles, is intended to be consolidated at high temperatures to produce a finished product.

[3] Ceramics Research Institute (CNRS / University of Limoges).